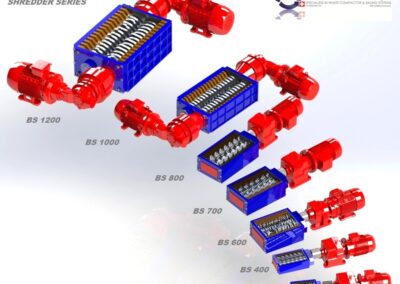

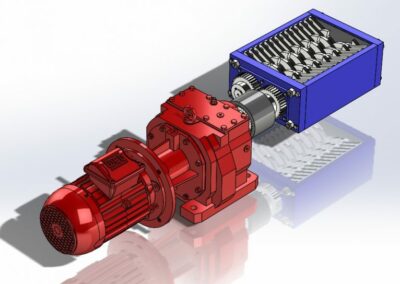

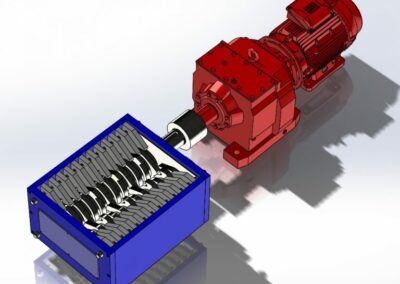

Shredders

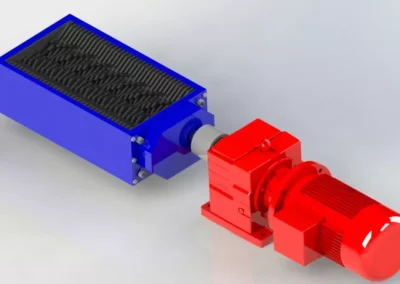

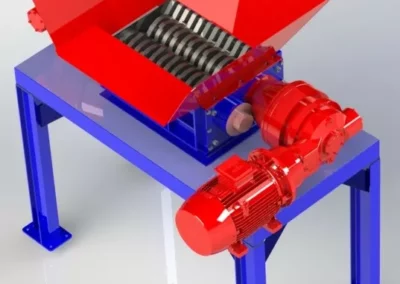

Bulkmatech Cape Dual Shaft shredder is commonly used in volume reduction, product destruction/separation, or primary shredding application.

These Variable speeds – High torque Industrial shredders are ideal for processing compactable material such as Rubber, Wood, Kraft, Light Metals, and Large variety of Plastics.Our shredder systems are very versatile, hardworking machines that can be configured to process a wide range of materials

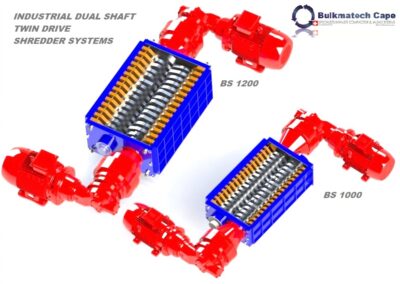

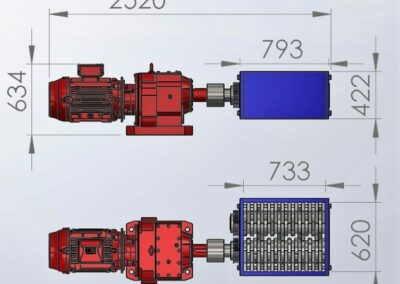

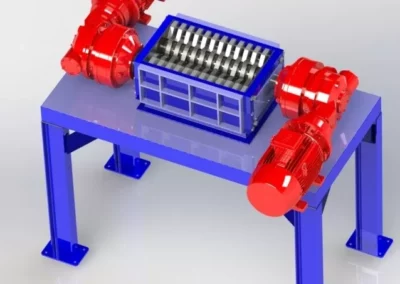

Dual Shredder

The right sized shredder is important. Bulkmatech Cape will recommend a shredder that is sized to need much less than 100% of its available power to do the job.

The reason for this is that as cutters dull with use, they require more power to shred. With an ample reserve power capacity, the performance of a shredder can be maintained for far longer before the cutters need to be replaced.

Bulkmatech Cape also recommends that a shredder be sized to grab only as much material as it has the power to shred. So besides model size and power capacity, considerations like cutter and shaft dimensions, in-feed chamber, and material properties need to be taken into account.

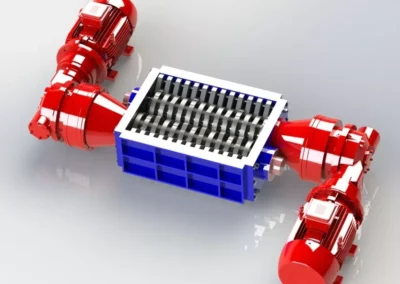

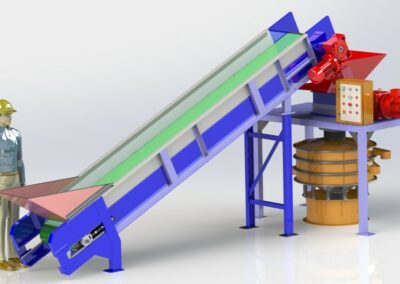

Food Product Destruction & Separation of packaging material from the food product.

Bulkmatech Shredders combined with feed conveyor and perforated stainless steel rocker bins create a turnkey solution for Food product manufacturers. This system can fast & effectively destroy packaged food products and separate the food from the packaging material. Shredded food packaging can now be cost-effectively disposed of as: Refuse Derived Fuel (RDF), General waste, or be recycled. The separate food product can be disposed of as: Biomass for Waste to energy, Composting, or Food for Pig farmers. This system as been proven to be extremely reliable, fast, and cost-effective.

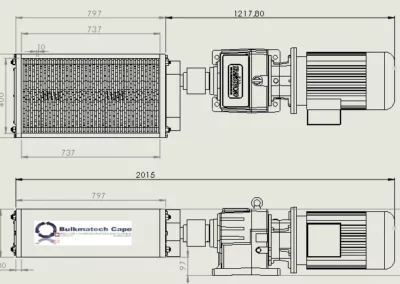

BS- 600 Shredder with feed conveyor

System designed to destroy and separate food products from packaging.

BS 600 7.5kw shrdder with Feed conneyor

System designed to destroy and separate food products from packaging.