Waste Balers

Bulkmatech Cape’s Baling Systems are designed to easily compress large amounts of recyclables ie. paper, cardboard, plastics, cans and drums into manageable bales. These machines are generally used when recycling is in place, in order to cut down transport costs, reduce carbon footprint and minimize storage space.

Baled recyclable materials receive a much higher revenue than loose recyclable materials.

These machines can also be used to destroy a clients waste product thus eliminating resale or consumption of product waste. A two-car garage filled with voluminous packing materials can be reduced to a single bale.

Did you know that in commercial businesses, for example, about 1cubic meter of packaging material is produced from approximately every 8cubic meters of floor space.

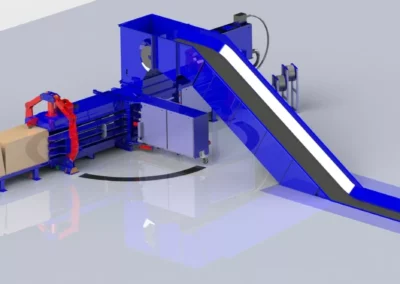

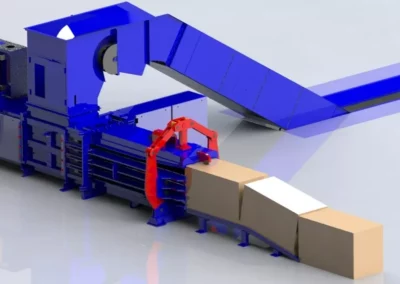

TOP LOADING HORIZONTAL BALER, BH – SERIES

These machines are used to achieve effective recycling. Baling systems will maximize profit, by reducing transport costs, reducing Carbon Footprint and minimize storage space to an absolute minimum .

Used to compress large amounts recyclables ie. Paper, Cardboard and Large Variety of Plastics.

Bales range in weight depending on model. ie from 110kg (Kraft K4) on BH-10 baler to 560kg (Kraft K4) on BH 28 & BH40 – series baler.

These Baler is available in several different “Door” and “Continues “models:

VERTICAL BALE PRESS

Specifications:

- Product type: Front loading vertical baler

- Application: Generally used for recycling to reduce transport costs, carbon footprint and storage space

- Materials compressed: Large amounts of recyclables such as paper, cardboard and plastics

- Bale weight range: From 45kg on BV-5 baler to 410kg on Orwak 3410 baler

- Models available: BV-5 (low density baler), BV-6 (low density baler), BV-7 (high density baler), Orwak 3420 & 3820 (high density balers)

- Power options: 3 phase- 380V, single phase 220V or petrol engine

CAN/BOTTLE CRUSHER

The Bulkmatech BC-Series Can or Bottle Baler is a machine designed to compress large quantities of various types of cans and bottles, including those containing liquid products.

The baler can handle drinking cans, paint tins, aluminum or tin cans, as well as plastic PET, LD and PVC bottles. It is primarily used for recycling purposes to reduce transportation costs, minimize storage space and reduce the carbon footprint.

The machine is also very effective in separating food products from packaging material, allowing for recycling of the packaging and disposal of food waste as either, Bio compost, pig feed or general waste.

This is very usefull for Food or Pharmaceutical manafactures.

The BC 400 can destroy all defective product and seperate from the packaging material all on site. Gaurenteeing the manacfucture a “cradle to grave” philosophy.

The baler is equipped with a press force of 26 tons and is available in different models with varying bale size and weight, depending on the model. For example, the BC-400 model can create a bale size of 40 x 40 x 7mm and consists of up to approximately 260 cans, with a weight of approximately 7.5kgs. The machine is available in two models, with or without liquid extraction upgrade, and two power options: 3 phase- 380V or 14hp Petrol engine BC-400 or BC-450.

DRUM CRUSHER – DB – 21

Product Name: Bulkmatech Cape DB-21 Drum Crusher

This drum crusher is designed to crush 210 Ltr steel drums down to 75mm. It features 23 tons of compaction force, making it capable of crushing even the heaviest steel ribbed drums. The system can be operated using either electric PLC push-button control or a hand-operated control valve. It also includes a catch basin to collect fluids that drain during compaction. The drum top is punched with venting blades, and a closed splash guard with a control window is provided for safety. An explosion-proof version of the BD-21 is also available.

Specifications:

- Press Force: Up to 23 Tons

- Compacted height of crushed drum: Approximately 75mm

- Stoke: 1025mm

- Compacting Cycle per drum: Approximately 40 seconds

- Weight: Approximately 1.3 tons

- Power Options: 5.5 KW 3 phase- 380V or 14 HP Petrol engine